project name |

Technical specifications |

|

High frequency X-ray generator |

Select the configuration model according to actual needs |

|

Radiation angle (°) |

40°×40° |

|

Focus size (mm) |

3.0mm |

|

Controller size (mm) |

Φ264×458(mm) |

|

Controller weight (kg) |

11kg |

|

Maximum penetration (mm) |

45mm( F=700mm、T=25min、I=3.0mA、U=200Kv) |

|

Kilovolt adjustment range (kv) |

80 ~200(kv) |

|

Milliampere adjustment range (mA) |

0.5 ~3.0(mA) |

|

Max output power (w) |

900(w) |

|

Protection temperature (℃) |

85℃ |

|

Storage temperature (℃) |

-25˚C~ +70˚C |

|

Supply voltage (v) |

AC196 ~ 260 V / 50~60 Hz |

|

(It is recommended to use YG-D200G X high frequency X-ray flaw detector)

1.1 Main performance:

n Continuous operation at 200 kV/3 mA at 35℃.

n Wide input voltage range, suitable for various generator power supplies.

n Light weight, strong penetrating power and stable performance.

n More suitable for use in harsh conditions and humid environments.

n Intuitive control interface, easy to operate.

1.2 Main technical parameters

The detector of this digital image detection system is a high-quality portable flat panel detector. The detector has a pixel resolution of 125μm and supports multiple timing modes. However, the detector can be powered by a battery. After the battery is fully charged, it can continuously shoot more than 1,000 videos and supports both wireless and wired control solutions. It can be installed on mechanical equipment and can be equipped with various protective covers for the convenience of on-site operators.

2.1 Main features

n Weld inspection, pipeline flaw detection, explosives and other hazardous materials inspection, other X-ray applications.

n Reliable amorphous silicon image sensor technology.

n Pixel size 125 μm, grayscale 16 bits.

n Drop-proof, IP54 dust-proof and moisture-proof, 180-second exposure window, 3-second full-resolution image acquisition time.

n Built-in 1mm thick tungsten shield, can withstand 370kV radiation, 7mm narrow bezel, 2.5 hours battery life.

n Frontal load at least 100 kg.

n Supports continuous image acquisition at 1 frame/second.

n Support wired and wireless data transmission.

2.2 Technical specifications

n Image sensor: amorphous silicon

n scintillator: GOS

n pixel matrix: 2000*2400

n Picture area: 25cm*30cm

n AD conversion: 16 bits

n Image reading time: 3 seconds

n Dynamic range: 72 dB. Energy range: 40–370 kV.

n Spatial resolution: 4LP/mm

n Appearance size: 340mm*292mm*18mm

n Weight: 2.3 kg (excluding internal protection and handle)

n Shell material: aluminum alloy, carbon fiber plate.

n Data/signal transmission

Wired: Ethernet 1 Gbps, >100 Mbps

Wireless: 802.11 a/g/n, 2.4G or 5G, >100 Mbps.

n Trigger method: software trigger

n Software: Built-in special software for radiographic image processing.

n Temperature: -10~40 degrees (working)

-20~55 degrees (storage and transportation)

n Humidity: 20-90% RH (working, non-condensing).

Relative humidity 10-95% (storage and transportation, no condensation)

n Vibration: IEC60074-2-6 (10-200Hz, 5g)

n Shock: IEC60074-2-29 (16 ms, 10 g), radiation resistance 2000 Gy.

n Standard certification: CE, ROHS

3.0 Image processing software

Image contrast, brightness, gamma adjustment, the software provides a variety of image processing applications (such as image inversion, rotation, mirroring, etc.), image enhancement can be applied to identify defects more clearly, all images can be saved as 8-bit or 16-bit, Software engineering supports control.

4.0 Tablet Imaging Software

This tablet software is suitable for a variety of industrial digital inspection jobs. Image, including dynamic control, static control, image acquisition, processing non-destructive radioactive digital imaging, with the following functions: processing, image quality analysis, defect geometric size measurement, marking defects, image storage, automatic control, test report output software and detection software.

5.0 Laptop Workstation

Configuration requirements (depending on make and model at time of delivery):

n Genuine Windows operating system (win7, win10, win11)

n I7 processor, base frequency above 2.2GHz.

n Memory at least 8 GB.

n Discrete graphics card.

n Wireless Network – Wireless AC 9560, 802.11ac, dual-band MU-MIMO.

n Smart card reader, HDMI interface, USB3.0 interface.

n Minimum 500 GB hard drive.

1.0 Basic information

n Equipment name: X-ray digital image detection system V1.0

n Specification model: YG-DR01

n Image transmission method: wireless transmission

n Applicable pipe diameter: φ510~φ1219mm (optional rails according to user needs)

2.0 Hardware configuration list

serial number |

Equipment and accessories |

Specifications/Models |

manufacturer |

quantity |

Remark |

1 |

Device 1 (carry image acquisition board) |

YG-PC10 |

DDYG |

1 set |

equipment |

2 |

Device 2 (carry X-ray generator) |

YG-PC11 |

DDYG |

1 set |

equipment |

3 |

Flat panel detector |

CareVision |

Careray |

1 set |

Accessories |

4 |

Image processing software |

Ver 20.21.10.16 |

DDYG |

1 set |

Attachment (DR system) |

5 |

Image workstation |

HP 99 |

HP |

1 set |

Attachment (DR system) |

6 |

High frequency X-ray flaw detector |

YG-D300G |

DDYG |

1 set |

equipment |

7 |

High frequency X-ray pipe crawler |

YG-G100A1 |

DDYG |

1 set |

equipment |

8 |

Auxiliary rail (One specification is optional) |

φ510~φ1219mm |

DDYG |

1 set |

Attachment (DR system) |

Device name |

Portable digital image inspection system |

|

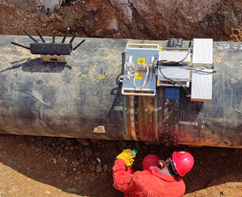

Equipment photos |

|

|

Device name |

Digital pipeline visualization system |

|

Equipment photos |

|

|